|

|

|

|

|

|

|

|

|

|

| ~ Senior Thesis E-Studio |

User Note:

Note: While great efforts have been taken to provide accurate and complete information on the pages of CPEP, please be aware that the information contained herewith is considered a work-in-progress for this thesis project. Modifications and changes related to the original building designs and construction methodologies for this senior thesis project are solely the interpretation of Katie Sennett. Changes and discrepancies in no way imply that the original design contained errors or was flawed. Differing assumptions, code references, requirements, and methodologies have been incorporated into this thesis project; therefore, investigation results may vary from the original design.

|

|

|

Building Statistics

- Building Name: Kennedy Krieger Institute - The Harry and Jeanette Weinberg, Developmental Disabilities Center

- Location: 801 North Broadway, Baltimore, Maryland 21205

- Building Occupant Name: Kennedy Krieger Institute – Outpatient Medical Center

- Occupancy of Function: Outpatient Medical Center and Developmental Disabilities Center

- Size: 106,000 SF

- Number of Stories above grade: 6 Stories

- Start of Construction: January 22, 2007

- End of Construction: January 20, 2009

- Project Cost Estimate: $35,000,000

- Project Delivery Method: CM @ Risk

- Construction Manager: Whiting Turner Contracting Company

- Architect: Stanley, Beaman, & Sears

- Civil Engineer: RK +K

- Structural/MEP Engineer: RMF Engineering, Inc

- Landscape Consultant: Mahan Rykiel Associates Inc.

Architectural Features

- Design & Functional Components:

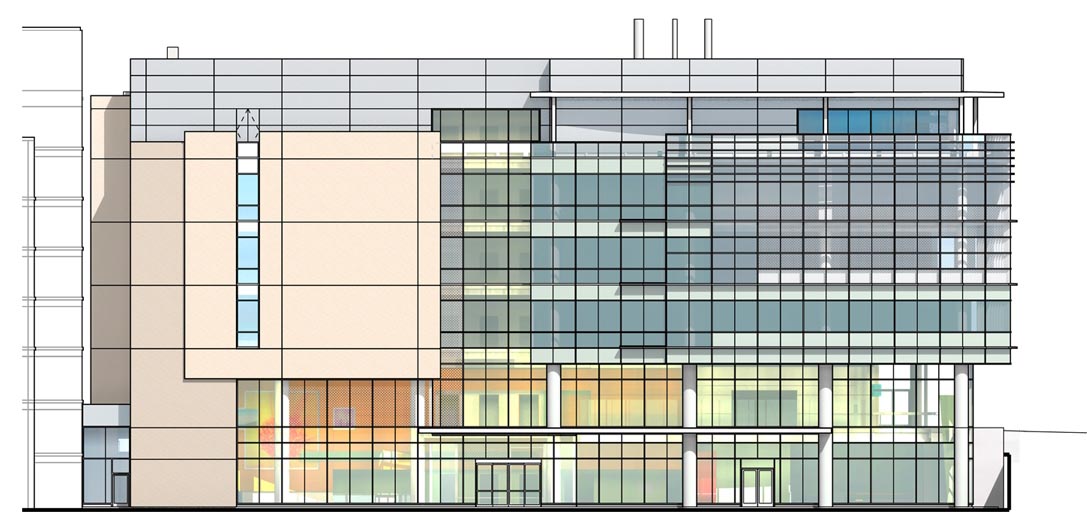

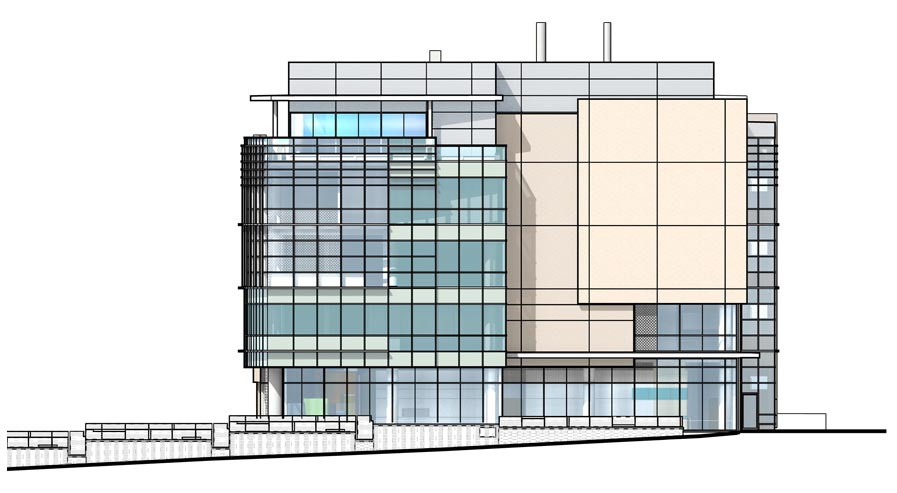

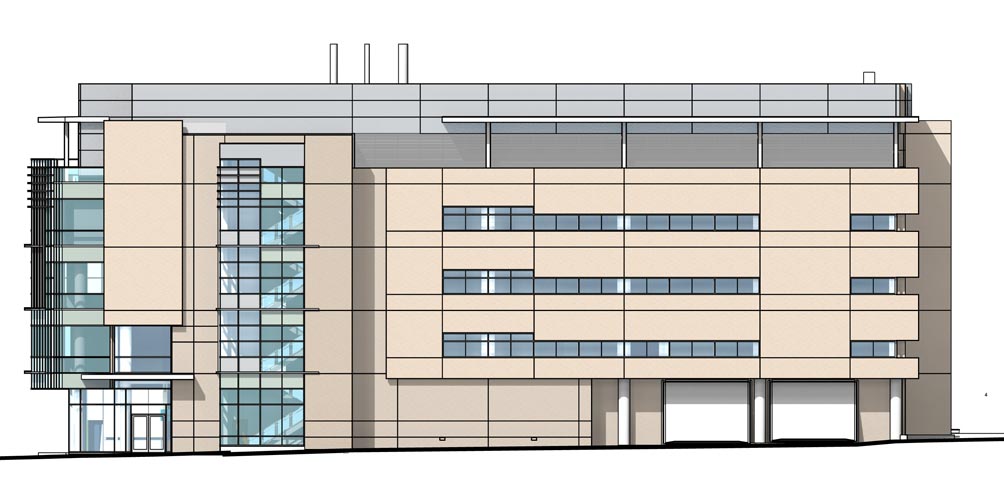

- The overall exterior design of the Kennedy Krieger Outpatient Center is pre-cast concrete panels and glass curtain walls. The overall function of the building is a medical center with each floor serving different purposes. The basement consists of the mechanical, electrical, and plumbing rooms, storage areas, and MEP technician offices. The first floor houses that child life area, security center, care center and several examination rooms. The second floor has a café, conference rooms, several offices, and the loading dock for truck delivery of supplies. The third floor has treatment offices, the speech therapy and speech research rooms, and the hearing/audio testing, treatment, and research rooms. The fourth floor houses the spinal cord gym, several more examination rooms, and the bone density, casting, and x-raying rooms. The fifth floor has the pool mechanical room and several offices. The sixth and final floor houses the therapy pool, the penthouse, chillers, and the three air handling units. The penthouse houses all mechanical, electrical, and plumbing equipment

- Major National Codes:

- International Building Code 2000:2003

International Fire Prevention Code 2000, 2003

International Mechanical Code 2000, 2003

Standard Gas Code 1999

NSPC 2001, 2003

National Electrical Code 1999, 2003

International Energy Conservation Code 2000, 2003

- Zoning: Currently Gathering Information

- Historical requirements:

- There were no historical requirements for this project. The site prior to the construction was a parking lot. Therefore the project is new from the ground up

- Building Envelope:

- There are two main systems that make up the building envelope. The first is the Glass Curtin Wall which covers about 50% of the North side and 50% on the West side. The curtain wall is connected at each floor by means of steel hangers welded to steel imbeds in the concrete floor slabs. The second system is what makes up the majority of the building envelope. This system, from interior to exterior, consists of gypsum wall board, glass fiber insulation – batt, semi-rigid insulation – pre-cast, and architectural pre-cast concrete wall panels. This system is connected in the same manner as the glass curtain wall

- Roofing System:

- The roofing system consists of hollow sheet metal construction that includes fully mitered and welded corners, integral counter flashing, and internal reinforcing. Sheet metal is hot-dipped in aluminum zinc alloy. Waterproofing for the roof includes ethylene propylene single-ply roofing which is mechanically attached. Lightning protection rods and roof drains are located on the roof and all mechanical, electrical and plumbing components are located on the sixth floor penthouse area.

|

North Elevation

West Elevation

South Elevation

|

Major Building Systems

- Structural Steel:

- Structural steel is used on the sixth floor penthouse area. Wide flange structural steel is carbon steel, ASTM A992, Grade 50. High strength bolts, nuts, and washers are ASMT 325 and have a mechanically deposited zinc-coating ASTM B695, class 50. Cold formed structural steel tubing is ASTM A500, Grade B material. The Structural steel is for the cooling tower framing, elevator connections, and to enclose the roof area.

- Cast In Place:

- The entire Medical center is cast in place concrete; this includes the foundation mat system, floors, and columns but excludes the 6th floor roof system which consists of structural steel. The foundation system consists of several mat slabs which are placed under the elevators, the columns, and exterior walls. Foundations are approximately 3 feet thick and vary in surface area depending on the item is it supporting. The floors are a pan and joist system with a floor thickness of 6 inches and joist spacing about every 8 inches on center. The columns are an average size of 30 inches in diameter and are located about every 24 feet from north to south and about every 29 feet east to west. Concrete compressive strength used throughout the building is 4000 psi concrete

- Precast Concrete:

- The exterior façade is made up of architectural precast concrete panels. Panels are made with a minimum of 5000 psi concrete, 28 day strength, and air entrained 5 to 7 percent. Connection devices are all stainless steel, which are connected to embedded plates, and angels. Grout is to be of a minimum strength of 10,000 psi, 28 day strength and will be tinted to coordinate with panels.

- Mechanical System:

- The mechanical system is a VAV system that consists of 3 air handling units with 40,000 cfm. There is also 1 air handling unit for the natatorium which has a 5,500 cfm. There are 2 chiller units with a 245 ton capacity. The chiller towers are located in the penthouse. Mechanical rooms are located in the basement and one mechanical room is located on the fifth floor and is for the natatorium units only.

- Electrical System:

- The Outpatient Medical Center uses 2500 amp power source that enters the building at its main switch board. The building also has twenty one 480/270 3 phase distribution switch boards and forty four 208/120 3 phase distribution switch boards and a 1500kVA transformer. The lighting in the building is mainly 277 volt lighting fixtures.

- Curtain wall:

- The curtain wall consists of aluminum frames with vision glazing and glass infill panels at the building’s exterior as well as the canopy at the front entrance. The glazing used is one of five different types of glazing, some are tempered and some are filter, all are tinted.

|

|

| |

|

|

|